TAG | led fixtures

19

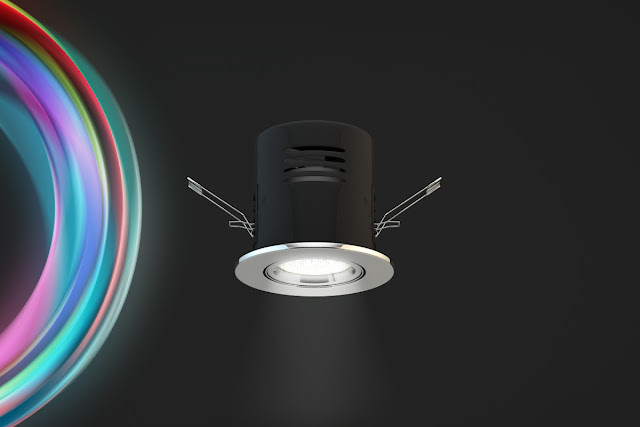

Megaman’s User Serviceable Led Lighting Solutions

Comments off · Posted by admin in LED, LED downlights, LED GLS, LED GU10, LED Spots

Megaman are pleased to announce that they now offer serviceable LED solutions for a range of applications.

Across its LED product development in replacement lamps, modules*, light engines** or fixtures, MEGAMAN are pleased to announce that they are now able to offer user serviceable LED solutions. This decision has multiple benefits. Not only can MEGAMAN LED light sources be serviced and upgraded to the latest LED technology, but by using serviceable solutions, existing luminaires can be retained, minimising the environmental impact of progress. This approach overcomes some of the inflexibility previously experienced by end users, of completely integrated LED solutions.

MEGAMAN also recognizes that some basic light fixtures have such a low carbon footprint that engineering for replacing the LED may not always be viable and it can be greener to replace the whole fixture. MEGAMAN fixtures in this category are 100% recyclable with component parts that can easily be dismantled and separated. They are still designed with serviceability in mind so have commonly used fixings or sizes for easy replacement long into the future.

For MEGAMAN LED modules, light engines and fixtures it is recommended that the installation and servicing is performed by a qualified and competent expert.

The MEGAMAN LED product range offers the highest degree of design freedom for lighting designers, both in terms of addressing future advances in LED technology, as well as offering a wide range of colour and output choices.

* LED Module is a unit supplied as a light source. In addition to one or more LEDs it may contain further components, e.g. optical, mechanical, electrical and electronic components, but excluding the control gear.

** LED Light Engine is the combination of one electronic control gear, integrated or remote, and one or more LED modules.

For Megaman LED lighting solutions, please visit www.novelenergylighting.com, or call 0208-540-8287 to discuss your project needs.

led fixtures · megaman · Megaman LED · megaman led lamps · megaman led lighting · megaman led luminaires · Novel Energy Lighting

Ivan Perre is an electrical engineer for London Underground working within the integrated stations programme. Lux sat down with Perre to talk LED testing and plans for the future of the Underground.

We need to know how products will perform

I’m involved in a number of areas in lighting for Transport for London (TfL). While I’m an engineer by day, the majority of my work is in verification and testing of LED systems. I’ve researched in the field of photometry and how LED light is measured, and I have subsequently developed methods to more accurately determine LED lux levels. This means that we can have greater confidence in the products we specify but also have a better understanding of how they perform in the field.

We test products really carefully

Any new technology, such as LEDs, is under scrutiny and we have a responsibility to our customers to ensure there is sufficient light.

The optical filters used in lux meters are designed to replicate the responsiveness of the human eye. This is characterised by the spectral responsivity of the lux meter, which is a bell-shaped curve. By using some tracing software, I am able to trace out the graph and convert it into data, which I can then extrapolate to get the values for each wavelength.

Once this is done, I am able to simulate the given light and find out what the lux value would be, and then I can compare it to the ideal lux value.

This process ensures that we can collect accurate and important data, specify the right products for the job, but more importantly deliver a better service to our customers.

We’re thinking outside the tunnel

One of the challenges we face at the moment is implementing feature design more effectively. We are starting to change the way we think about the station environment and in the future, we want to use light in different ways to highlight certain areas, introduce contrasts and create different atmospheres.

This is especially important as we’re looking at potential retail opportunities down the line, which have a number of other prerequisites in terms of lighting designs and outcomes.

“In the future we want to use light in different ways to highlight certain areas, introduce contrasts and create different atmospheres”

The new Night Tube service is a maintenance challenge

The new Night Tube service is a maintenance challenge

One of the main priorities for TfL is to try to reduce maintenance. This is becoming more important with the Night Tube coming up, which is a round-the-clock service on Fridays and Saturdays on the Jubilee, Victoria, and most of the Central, Northern and Piccadilly lines.

This will significantly eat into our engineering hours, and we want to reduce the number of interventions required where lighting is concerned. The longevity of LED lighting is a big factor in assessing the suitability of new fittings, as they don’t need re-commissioning as often.

Stations need a consistent look and feel

One of the most important projects we’re undertaking at the moment is a series of substantial works across a number of stations to create an integrated look and feel between new and existing elements.

We’re working with Crossrail to assimilate the interface zones between services, so there is a consistent feel between the two and not a stark contrast when you leave one service and enter another.

Test schemes make a big difference

We’re lucky to have a number of successful test schemes at TfL to reflect on, which invariably inform new projects. A couple of years ago we implemented the first LED column lighting system on the underground at Wimbledon Park tube station, which was a turning point in upgrading lighting systems as it proved to deliver huge energy and maintenance savings.

Smart controls need to be smarter

One of the things we need at TfL is to be able to change the drivers once they’ve failed without the need to program them. We want the new drivers to operate within the current system as close as possible and when they don’t it’s an issue. When there is only a short hour shift, it’s difficult to go around re-commissioning fittings if there’s a lot to do.

We’re very keen on controls and there are a number of benefits including maintenance, energy and functionality. With a new design idiom being developed for TfL, controls will become an imperative as we’ll need to control individual lights to provide different levels and different intensities.

We’re harnessing the power of procurement

I’m also involved in procurement of lighting technology and innovation in Europe through the Pro-Lite project. The project allows public sector authorities across Europe to team up and pool resources. That way it’s easier to procure innovative technology and consolidate our procurement power to create economies of scale.

The idea is to set technical standards and specifications to create opportunities for improved lighting solutions throughout member states. We have recently released the technical specifications that we’re going to use to go out for tender and we’re also in the process of finalising a whole-life cost model, so we can make like-for-like comparisons of light fittings.

I’m excited about new lighting technologies

I like the idea of using organic LEDs (OLEDs) although I’m not sure how we’d be able to use them in our material compliance. I also like the look of remote phosphor as it sounds like it’ll be a big step up in terms of efficiency.

Visit our main website today to explore LED lighting technologies for your retrofit project.

LED fittings · led fixtures · LED lamps · led lighting · led underground · london underground · lux · Novel Energy Lighting · subway lighting