CAT | Philips LED

As Philips announces they are investing in Li-Fi, this week we explore a new technology that has the ability to change the world. What is Li-Fi and how will revolutionise the way we receive the internet into our homes? Lux Today 21 February 2017

harold hass · li-fi · lucion · Novel Energy Lighting · philips led · smart homes · smart offices · visible light communication

The LED revolution has concluded, prices are falling and the industry’s attention is turning to the digital world, to the internet of things and smart cities.

In a Lux Today special edition, we examine smart cities and ask how is lighting improving our urban environments? Why are more and more cities adopting smart technology? And why does the lighting industry need to move quickly to take advantage of this new innovation?

data collection · li-fi · Novel Energy Lighting · philips citytouch · smart cities · smart street lights · visible light communication

6

Dubai rules all new properties must fit Philips LED lamps

Comments off · Posted by admin in LED, LED panels, LED Spots, LED Tubes, Philips LED

Fitting Philips ‘Dubai Lamp’, will be made the basic requirement for getting a Building Completion Certificate in Dubai.

Philips struck up a good deal!.. All new buildings in Dubai will soon be compelled by law to install specific LED lamps, the municipality has ruled, after striking a deal with Philips Lighting to supply millions of light sources to the emirate.

Authorities in Dubai signed a five-year contract with Philips to create the ‘Dubai Lamp’, which, it it is claimed, will be the first commercially available 200 lumen per Watt LED lamp.

The new fixtures will replace 80 percent of traditional lights currently in the emirate’s residential buildings, and, as of this year, all new buildings constructed in the city will have have to feature the Philips LED.

Fitting LED in new buildings will be made the basic requirement for getting a Building Completion Certificate, by the end of this year.

The initiative will initially focus on new buildings and big complexes such as schools, hospitals, mosques and shopping centres. A study will also be undertaken to develop a strategy of implementation for older buildings, in an attempt to ensure that the scheme ensures a wider legacy and that energy savings and a positive environmental impact continue to grow overtime.

Philips has been commissioned by the Dubai authorities to manufacture and supply two million of the ‘Dubai Lamps’, which will not contain mercury or generate heat. The Dubai Municipality plans to install 10 million Dubai Lamps before the end of 2021.

‘It will be made the basic requirement for getting a building completion certificate. This will be beneficial for both sides. The owner of the building will be able to save a lot of money on energy charges and we will able to protect the environment,’ Hussain Nasser Lootah, director general of Dubai Municipality, told The National.

‘In the beginning, we will concentrate on new buildings and we will complete a study of old buildings to see what can be done.’

Lootah said the latest agreement which is in line with government directives, supported the Dubai Integrated Energy Strategy, which targets a 30 percent reduction in energy consumption by 2030, and the Dubai Carbon Abatement Strategy, which is aimed at reducing carbon emissions by 16 per cent by 2021.

The lamps will be available in four models, both in cool daylight and warm white colours. That includes 1W candle lamps to replace the 25W incandescent lamp, 2W bulbs to replace 40W incandescent lamps, 3W bulbs to replace 60W incandescent lamps, and the 3W MR16 Spot to replace 50W halogen spots.

Novel Energy Lighting supplies the full range of Philips LED lamps, tubes, and luminaires. Please visit us today, or email: sales@novelenergylighting.com or call (0208-540-8287) to discuss you project needs.

dubai lighting · LED lamps · Novel Energy Lighting · philips led · Philips LED bulbs · philips led luminaires · Philips led panels · philips led tubes · philips lighting

19

Car Park LED Lighting Solutions – Philips PacificLED GreenParking

Comments off · Posted by admin in LED, Philips LED

Smart, energy efficient lighting at Globen parking garage with the PacificLED GreenParking system.

Sustainable lighting

The three-floor, 9,000 square meter garage has 1,500 parking places. The original existing lighting installation was divided into 4 zones per floor, each lit with traditional batten luminaires, each housing a 1 x 58W T8 fluorescent tube. When a car entered the garage, the lighting operated at 100% of its full output for two hours, before switching off completely. The lighting quality was poor, and the luminaires were starting to fall apart. When it came to the renovation, Klövern AB didn’t just want to replace the fluorescent lamps with LED lamps. The company wanted something more sustainable. “We’re highly committed to sustainability, so it was very important that we installed a ‘future-proof’ lighting system,” explains Lennard Lindkvist, Energy Manager at Klövern AB.

“We wanted a lighting installation that would produce bright, well-distributed white light, so the garage felt safe and secure for our customers. But at the same time, we wanted a smart, energy-saving system that would help reduce our operating expenses.”

Avoiding cabling costs

Klövern AB wanted to avoid the cost of replacing the cabling, meaning that the new LED luminaires had to be the same length as the existing fluorescent lamp luminaires. “After exploring various options on the market, we decided that the GreenParking system from Philips, which couples Pacific LED waterproof luminaires with wireless control, was the best long-term solution from a sustainability perspective,” continues Lindkvist. “We replaced the luminaires and kept the cabling, which saved significant labor and material costs.”

The complete GreenParking package

GreenParking is an easy-to-install, full lighting system: PacificLED luminaires paired with wireless movement detectors create a complete and controllable wireless lighting system, which enables the luminaires to communicate with each other and behave according to how they are programmed. “For the new lighting installation, the parking garage was divided into 13 zones per floor and more than 120 wireless movement detection sensors were mounted in strategic locations” says Lindkvist. “Unlike with our previous system, we’re only paying for lighting when it’s needed. When a car or pedestrian enters the programmed ‘zone’, the lighting comes on to 90% of its full power. When the car or pedestrian leaves the area, the output drops to 10% after 2 minutes”. “The LED lighting produces a crisp white light – essential for customers to feel safe and secure. And because Pacific LED luminaires are IP65 class rated, we know the luminaires are tough enough to withstand the exhaust gases.”

Halving energy costs

For Klövern AB, it was crucial that the new lighting system saved energy and cut operating costs: “Energy consumption is a major business expense for us – but also one we can address by investing in new technology. With every penny we save on energy, the property becomes more profitable”. “We’ve cut energy consumption by more than 50%. The LED luminaires account for 75% of the energy savings, the lighting controls 25%. “We’ve saved 350,000 kWh per year by switching to the Philips GreenParking system. In fact, we save as much energy as 17 houses consume every year.” The long life span of the LED luminaires means Klövern AB will also reduce its maintenance costs: “With the old system, we had to replace the fluorescent lamps every other year. The new LED modules won’t need replacing for 15 years. This not only saves time and money – it makes us a more environmentally friendly company as well.”

Contact us at www.novelenergylighting.com, T: 0208-540-8287, E: sales@novelenergylighting.com to discuss LED retrofit options for your car parking or outdoor lighting facilities.

car park lighting · led lighting · Novel Energy Lighting · philips car park lighting · philips greenparking · philips led · philips pacific · philips pacificled

5

Philips: 3 Factories 5 Star Lighting Solutions (Novozymes, Denmark – Case Study)

Comments off · Posted by admin in LED, Philips LED

Philips GreenManufacturing system has been installed in three production units. The functionality of the system can be adapted to individual areas based on behavioural patterns and the requirements of the people working there.

Project and requirements

Novozymes has three factories in which a large number of T8 neon tube light fittings needed replacing. Access conditions at all three locations were generally difficult, making a traditional cable-based installation very time consuming. The plan therefore called for reuse of the existing cable installation, coupled with an intelligent solution to be able to control lighting levels as needed and based on human presence. The aim was also to reduce electricity consumption and contribute to sustainable production. Furthermore, the two installation contractors, Lindpro and Electricom, had only four months from signing the contract to completing the work. “The installation process had to be flexible enough to give us the opportunity to optimise if modifications were made to the premises”, explains Peter FinkJensen, Senior Project Manager at Novozymes. Philips’ GreenManufacturing is a new lighting system based on LED fittings with integrated lighting control and wireless sensors. Acting upon the recommendation of consultant Sweco, GreenManufacturing was selected, as it met all of the requirements.

Requirements met by GreenManufacturing

The GreenManufacturing system has been installed in all three production units. Replacement was on a 1:1 basis, reusing the existing cables. A total of 4,400 Pacific and GentleSpace LED fittings were installed, plus 1,200 sensors able to communicate wirelessly with these fittings. No further installation work was needed, as the wireless sensors can be relocated when required. GreenManufacturing functionality can be adapted to individual areas based on behavioural patterns and the requirements of the people working there.

When no movement is detected after ten minutes, the light dims to 10%, and in designated areas switches off after a further ten minutes. “Our energy savings have been calculated to be around 4,600 MWh per annum. No replacement of tubes will be required during the lifetime of the fittings, which also saves us maintenance costs and, of course, disruption for production and the workforce,” says Peter Fink-Jensen. “Service life is expected to be around 15 years for 9-10 hours daily use,” explains Andreas Birch from Sweco, consultants for the project. “Credibility, quality products and a well-known manufacturer with a good track record that is able to provide the necessary support were the reasons we chose Philips”, adds Fink-Jensen.

“The project ran to plan, and the GreenManufacturing solution was installed at all three production facilities, four months after the contract was signed. Production runs around the clock and stayed uninterrupted throughout the entire project”, he stated.

Satisfied users

“We are very satisfied with the lighting. Large factory buildings like ours can be uncomfortable to be in if they seem dark, but the lights come on so quickly that it doesn’t feel insecure. The light intensity is also higher than from the old tubes”, claims Peter Kolby, an operator at the site. “The fact that the lights do not turn off completely is nice. By keeping them on at 10% means we can still see in the building, something that is necessary, not least from a safety point of view. When we work on the night shift, it’s really great to have full lighting throughout.”

Easy and fast installation

“Electricom was responsible for about half of the installation. Per Junge, installer and owner, is very satisfied with GreenManufacturing and the level of support provided by Phillips:

“Philips gave us thorough instructions to commission the system, and our electricians have nothing but good things to say about it”, he says, pointing out that GreenManufacturing system will definitely be used again in the future. “With the intelligent GreenManufacturing solution there was no need for new cables, which made it all very easy to install. I have already proposed the same solution to other customers”, says Service Leader Martin Fehrn from Lindpro. “The aim was to cut electricity consumption and contribute to sustainable production – and we certainly succeeded with GreenManufacturing”, says Fink-Jensen, Senior Project Manager at Novozymes and responsible for running the project.

Visit www.novelenergylighting.com to explore the Philips LED High Bay range, including Philips Coreline Highbay, and Philips Gentlespace LED. Tel: 0208-540-8287

factory lighting · led higbay · led high bay · led highbay · Novel Energy Lighting · philips coreline highbay · philips gentlespace · philips led · warehouse lighting

Philips recalls thousands of metal halide lamps over ‘burn and laceration’ dangers. PLUS: The latest business news including acquisitions. Lux Today webcast for 31 May 2016 is presented by Courtney Ferguson.

LED · lux reports · metal halide · Novel Energy Lighting · philips ipo · philips lighting · zika virus

24

Philips Lighting @ L+B 2016 – Experience light beyond illumination

Comments off · Posted by admin in LED, Philips LED

Philips Lighting showcased truly pioneering lighting innovations at Light + Building 2016, the world’s leading trade fair for lighting in Frankfurt, Germany.

Philips brought together leading experts to inspire and engage fellow professionals as part of their speaker program at light+building.

Connected lighting in smart cities

Delivering smart buildings

New technology trends and their impact on LED luminaires

We’ve captured these insightful talks in a series of videos – so if you couldn’t make it to the show, here’s your chance to catch up on what you missed.

connected lighting · iot · LED technology · light and building 2016 · Novel Energy Lighting · philips led · philips lighting · smart buildings · smart cities

17

The Brave New World Of The Internet Of Things – The Technologies And Issues

Comments off · Posted by admin in Infographics, LED, Philips LED

The IoT, in which every device can communicate with every other device – even a smart bedcover can ‘talk’ with devices such as Philips’ Hue LED lighting system – is fast becoming a fact of life, like it or not. But how are the IoT technologies evolving, what are the benefits and how about the risks? And how about a wider context? James Hunt explains:

Mario Morales, IDC

The IoT is as of countless ‘things’ that are fitted with uniquely identifiable embedded devices that are wirelessly connected to the Net. These ‘nodes’, as the ‘things’ are called, can send or receive information without human intervention. The nodes can even be fitted to animals (to track or find them), and indeed to people and their clothes – for a variety of reasons we may or may not like.

To achieve this, every ‘thing’ – which could be an LED light source or luminaire, or thermostat, or an industrial controller, for example – must be uniquely identifiable through its embedded computing system, yet it must also be able to interoperate within the existing Internet infrastructure. Such devices are proliferating fast.

With its myriad such devices, including sensors and actuators that ‘talk’ to each other wirelessly and on the Internet, the IoT brings with it an astonishing ability to measure, monitor, and analyse data. This includes, for example, consumer behaviours and buying habits – and not just consumers either, as all businesses can benefit.

Such monitoring and analyses can be used to determine future product developments that will revolutionise the ways in which we live and do business. For the vast majority of homes – made ‘smart’ by IoT devices – everyday life will be enhanced by technology, particularly in terms of entertainment and comfort.

To take just one example – Google and Philips Lighting have got together for Nest Lab’s intelligent wireless thermostat and home automation devices to work with Philips’ Hue IP-connected LED lamps – OSRAM is in on the act too.

Connectivity is the word

When the IoT is augmented with devices such as sensors and actuators, it can then encompass increasingly important technologies such as smart homes, buildings, grids and cities, as well as intelligent transportation. These devices collect useful data with the help of various existing technologies and then autonomously flow the data between other devices – such as those that use Wi-Fi for remote monitoring. But how, in brief, does such connectivity work?

Firstly, there are several types of connectivity used by the IoT. These are:

* Personal Area Networks (PAN)

* Local Area Networks (LAN)

* Neighbourhood Area Networks (NAN)

* Wide Area Networks (WAN).

PANs and LANs are those that most domestic and small business IoT installations are likely to use directly and these are also the ones that the majority of electrical contractors and installers will be involved with.

Those IoT devices that use a PAN with a smartphone will use the smartphone as the gateway to the Internet (WAN). Devices in a smart home or automated building can connect to a LAN and find their way to the Internet too.

So IoT devices use, as the name implies, Internet connectivity, but smart devices that are part of an overall IoT can also use other enabling technologies, such as RFID and near-field communication (NFC), optical tags and quick response codes (a now common example is the QR Code) and a whole range of wireless (Wi-Fi) topologies. The latter include Bluetooth Low Energy, low energy wireless IP networks, ZigBee, Z-Wave, LTE-Advanced (high-speed communication specification for mobile networks) and Wi-Fi Direct (Wi-Fi for peer-to-peer communication without needing to have an access point (AP).

It remains to be seen if any one of these becomes pre-eminent.

Important IoT issues

Away from IoT issues that will affect electrical wholesalers, contractors and installers directly – as opposed to regulators, data centre developers and owners, specifiers and IoT / network device manufacturers – there are a number of problems that will need to be addressed to ensure successful wide-scale take-up.

For example, thousands of IoT devices signaling and sending data to each another take both CPU consumption and a surprising amount of energy. This costs money and has carbon emission implications, so IoT devices should use the minimum energy possible. Though this will not normally affect electrical distributors, contractors and installers, ultra-low-power wireless chipsets should be used in IoT devices and low power networks – such as Bluetooth low-energy, ANT, ANT+, ZigBee, ZigBee RF4CE, Wi-Fi, Nike+, IrDA and the near-field communications (NFC) standard.

Bandwidth take-up is another IoT connectivity issue. Bandwidth on a cellular (mobile) network is expensive, especially with hundreds of thousands of IoT devices sending request/response signals to a server – the result is that the server farm will need to be large enough to handle all the data. With the potential for many billions of devices (possibly even trillions longer term), this will be a huge problem that must be addressed.

Another issue is presence detection of IoT devices. This provides the exact state of all IoT devices on a network and shows immediately when any device drops off the network – or when it comes back on. In this way, the IoT devices can be monitored (and fixed if a problem occurs).

And for those IoT devices that ‘live on their own’ – such as trackers – the connectivity to the wider Internet can be tricky.

Finally, it is important to note that the Internet is not simply one network, and heterogenous networks, proxy servers and security firewalls can all disrupt connectivity. So a fully functioning, all-encompassing IoT is not with us yet as many issues need to be sorted. Even so, the vast majority of Voltimum users will not need to confuse themselves with this level of granularity – most already available smart devices they install for domestic use as part of the IoT will be simple to install and commission. They are already.

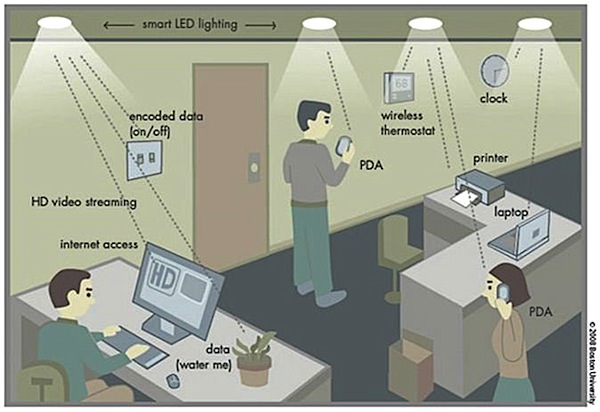

At light speed!

Although Wi-Fi has not been in the public domain for too many years – apart from computer routers – it is now an established means of data communication. It is fast and increasingly reliable. Importantly, it is quick and easy to install because expensive and disruptive hard wiring is not needed.

However, there’s a new kid on the block that is even faster – far faster – and it has its own set of advantage and disadvantages. Let’s look at it briefly here:

This important newcomer is Li-Fi, which has as its analogue Wi-Fi, but being based upon light (which travels at 186,000 miles/s) is very much faster – many times faster than conventional Wi-Fi – and possibly up to 10 times cheaper.

Li-Fi (or Light Fidelity) is a form of visible light communication (it can also use infrared and near ultraviolet). It is bidirectional and fully networked and has been described as a ‘new era of wireless connections’. With claimed speeds of up to 224 GBps (though mostly lower), this new technology could enable a high-definition film to be downloaded in seconds.

The change to Li-Fi, when it comes, will be driven mainly by the electrical and lighting sectors through LED lighting. Li-Fi will turn every LED lamp into wireless access points (APs), which effectively allows any user to move between sources without losing the connection. The LED lamps act as the medium to deliver networked, mobile, high-speed communication in a similar manner to Wi-Fi (but much faster). All this then becomes another enabler and part of the IoT.

Li-Fi has the advantage of being suitable for use in areas sensitive to electromagnetic waves such as aircraft cabins, hospitals and nuclear power plants, because it does not cause electromagnetic interference. However, the light waves cannot penetrate walls, so reducing Li-Fi’s scope, and there may be problems in bright sunlight. Such difficulties will have to be addressed before there is widespread use of Li-Fi, but there’s no doubt that this new technology is creating great excitement.

Already there are examples of Li-Fi in the market. For instance, Philips Lighting has developed a system for shoppers in stores. They have to download an app on their smartphones, which then work with the lighting LEDs in the store. The LED light sources can pinpoint where the shoppers are located in the store and give them corresponding coupons and information based on which aisle they are on and what they are looking at.

Li-Fi is very likely, therefore, to change data communication; importantly for the electrical and lighting sectors, it will also generate much-needed new revenue.

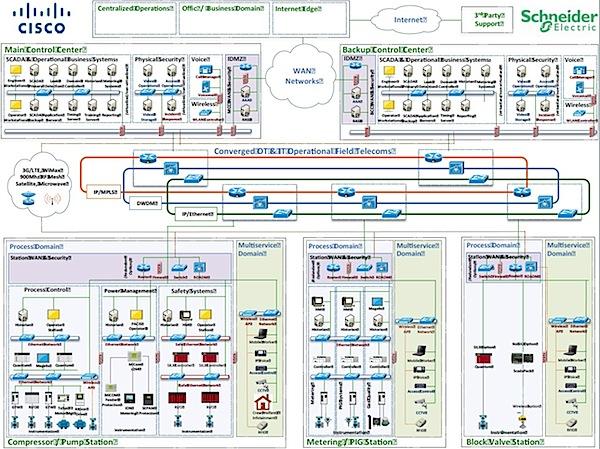

Ethernet and Industrial Ethernet with the IoT

The IoT doesn’t only have domestic applications; it has a vast potential in commercial, retail, hospitality and public building sectors too. Then there’s industry – in particular, manufacturing and process plant. A connectivity protocol that is very widely used in IT is Ethernet and its industrial counterpart is the much more rigorous Industrial Ethernet. These, together with Wi-Fi are effectively enabling the Manufacturing Internet of Things – otherwise known more usually as the Industrial Internet of Things (IIoT).

The (IoT) has morphed from its RFID origins to one that encompasses all networked devices, both within and without a manufacturing operation. The big drive to adopt IoT in manufacturing has coincided – says Automation World – ‘with a concurrent enabling trend toward use of Industrial Ethernet and wireless (Wi-Fi) network technologies within the production environment’.

In addition to intelligent sensors and machines, the IIoT also takes in ‘Big Data’, cloud computing, analytics, mobility and what is termed universal visualisation. Manufacturers are aiming to implement the IoT or IIoT to optimise assets, increase production efficiencies and, therefore, improve business performance. This is achieved by gathering data from the many sensors, actuators, other devices, machines and controllers operating on the shop floor. This data is then made globally available via a cloud or similar infrastructure platform to those operators who have the authorisation (and for security’s sake, only them), so that they can monitor and analyse it – and act upon it if necessary.

The application of the IoT and IIoT to industry is really beyond the scope of this article, and relatively few Voltimum users are likely to be involved in the sector, but it is important to note, even so, how the IoT is having a crucial impact here already.

Security and safety will be crucially important

There’s that proverbial fly in the ointment, of course, and this is security, which will be of paramount importance if the future all-encompassing IoT is to work as intended, safely and securely. This is because just about everything (and everybody) will be connected together. The possibilities for hacking, denial of service, fraud and utility- and city-scale disruption are huge.

Indeed, security concerns are developing faster than even the IoT itself. This is especially so when it is considered that IoT devices will be (and already are) connected to smart grids, smart cities, water and gas utilities, energy organisations, transport etc. And domestic smart meters will connect homes to power utilities. Knowing this, the potential for catastrophe is certainly clear, whether by accident, by virus intrusion or via hacking.

So among the many considerations will be to ensure that when sending or receiving data, the IoT device or server must have proper authorisation for that (and every such) action. Also, an IoT device is dangerously vulnerable when it is listening to an open port out to the Internet – ports should not be open, despite the need for bidirectionality. End-to-end encryption between devices and servers will be crucial.

But security doesn’t just mean ensuring that your IoT system is secure from hacking; it also involves privacy and whether you can be spied upon, because the IoT holds the possibility that organisations will be able to intensify personal surveillance. And if they can, you can be sure they will try.

Issues include when someone sells a house with a smart thermostat or garage door, how does the new owner ensure former users can no longer access these devices? And how do manufacturers protect against intrusions into smart TVs and theft of data collected from device cameras and microphones? Such issues have to be addressed to make the IoT safe and secure, now and in the future.

Standards

It is clear that IoT and connectivity standards are already a crucially important, though already divisive topic. After all, how will devices connect to others without interoperability standards? Yet, many devices so far conform to a wide range of often non-interoperable standards.

Cross-industry open source organisation, the AllSeen Alliance (among others) believes that the IoT cannot meet its full potential without an open platform to ensure interoperability between devices from different manufacturers.

Then there’s research by ON World, which finds that the wireless standard ZigBee, already being used by many IoT devices, continues to increase its share of the IEEE 802.15.4 and smart home markets. By 2020, the study claims, ZigBee standards will be used in eight out of 10 of the 802.15.4 chipset shipments.

Furthermore, the Thread Group announced last year that it had completed the specification and documentation for its IP-based wireless networking protocol for low-power connected devices in the home.

These represent just a very few examples of potential interoperability clashes for connected and IoT devices. Therefore, organisations such as the Institute of Electrical and Electronics Engineers (IEEE), the Industrial Internet Consortium (IIC), and the European IoT-A (Internet of Things – Architecture) project, among others, are looking to provide architectural frameworks that define relationships between IoT domains and devices, as well as appropriate security schemes.

As these few examples show, it’s clear that there is much work to do as far as standards and interoperability are concerned.

And finally….

For the future? Well, the World Economic Forum makes five predictions for the IoT, bearing in mind that in the past year alone, IBM has invested £2 billion in its IoT business unit, and AT&T announced a record 1.6 million connected device net additions, including one million IoT-enabled cars, in Q3. Earlier in the year, Samsung declared its commitment to connecting everything it sells by 2020, and GM stated that its OnStar 4G capabilities will generate £242 million in profit over the next three years.

The predictions are:

– That the ‘security of things’ will take centre stage.

– We will stop counting the ‘things’ in favour of more important success metrics to put a premium on the quantifiable impact of new services.

– For the first time, more new cars will be connected than not.

– Low-power wireless area network (LPWAN) technologies will not go mainstream because the technologies are still in their infancy.

– The IoT market will align around a more precise lexicon, meaning that ‘business savvy enterprises will demand accuracy and accountability, resulting in clearer definitions from IoT solution providers’.

internet connected lighting · internet of things · iot · iot led lighting · led lighting · lifi · Novel Energy Lighting · philips hue · wireless control

16

Can power over Ethernet transform how we control lights in the workplace?

Comments off · Posted by admin in LED, LED downlights, LED panels, LED Spots, Philips LED

Lux reports: LED lighting is helping buildings around the world slash their electricity bills because the amount of energy needed to run LEDs is so much lower than that consumed by traditional forms of lighting.

But lower energy consumption isn’t just about saving money and being kind to the environment. It’s starting to demonstrate other benefits too.

The electrical load of LED sources is now so low that you don’t even need mains cables to power them – you can use standard network cables, so it’s easier and cheaper to connect and control your lights.

This technology is called ‘power over Ethernet’ (PoE) and, as the name suggests, it’s a way of providing power for electrical equipment through Ethernet cables – the same ones that already form the backbone of the IT network in your office.

Ethernet uses ‘cat 5’ (or more recently cat 5e or cat6) cables – the kind you plug into your router, with the plastic clip on the end that clicks into place.

Cat 5 cables are really designed to carry data, not power. But as long as the load is below a certain wattage (up to about 60W at the moment) they can power and communicate with devices at the same time. Which turns out to be really useful.

So what are the advantages for lighting? Well, everyone knows that wiring up a new lighting system can be an expensive headache, and to install a control system, you’ll need yet another network of wires up in the ceiling, along with the power cables.

If you want control but can’t face all that wiring, you’ve got three options: send the data wirelessly (using specially equipped drivers), send the data over your power cables (using power-line communication, offered by the likes of Lumenpulse and Echelon), or send the power over your data cables – in other words, PoE.

The great thing about using cat 5 cables for this kind of thing is that they’re cheap to buy and even cheaper to install – no need for an electrician, just click the cables into place and you’re away. Philips, one of the suppliers of power over Ethernet systems for lighting, reckons installation is up to 25 per cent cheaper than conventional wiring.

But that’s just the beginning – the real savings are in the longer term.

The next big advantage is the level of intelligence that an Ethernet-based control system can bring. Every light becomes a point on a network, with its own IP address. That makes it easy to control and monitor them (including remotely over the web), and if your light fittings incorporate presence sensors, temperature sensors, light sensors and so on, you can track that data too.

PoE brings lighting into the ‘internet of things’, allowing you to connect your lighting to other devices and systems in the building, such as heating, ventilation, IT services and security. The facilities manager has a single system that shows exactly how the building is being used.

Up and running

Philips already has a PoE lighting control system up and running at a new Amsterdam office building occupied by accountancy firm Deloitte.

UK-company Prolojik also has a power over Ethernet system, Light Matrix, that it sells with luminaire makers Future Designs and Phi Lighting. The system is installed in a meeting room at the offices of PricewaterhouseCoopers in central London, to power and control 20 direct/indirect luminaires.

Other companies working on PoE for lighting include Iowa-based Innovative Lighting and California’s Nuleds.

To use Prolojik’s power over Ethernet system, you need a black box called an Ethernet switch, which converts AC mains power to the DC that goes through the cat 5 cables (achieving 10 per cent efficiency savings over a standard setup where mains power goes all the way to the driver, Prolojik says). Once the switch is installed, the electrician’s work is done. It can power up to 3kW of lighting: it has ports for 48 cables, each of which can be used to power and control 60W of lighting – enough for maybe one or two luminaires each. Any luminaires rated up to 60W can be used with the system, although it does require Prolojik’s Dali drivers.

Mark Vincent, commercial director of Prolojik, says the ease of installation is a big draw for clients. ‘When we’ve been presenting this, I’ve been apologising to electricians and contractors, because we’re taking their business away,’ he says. But the real benefits are in fully addressable control of lights, and the long-term energy-efficiency benefits.

As with Prolojik’s system, the Philips system works with third-party luminaires, and talks to any existing control systems that may already be installed in a building. Philips’ PoE system is based on a network of small Ethernet switches, so it can be scaled from powering a handful of luminaires to 1,000 of them.

Jeff Cassis, senior VP of global lighting solutions at Philips Lighting, says: ‘You can extract whatever data you want, whenever you want. Not only can you monitor energy consumption per light source, you have this really granular ability to look at what’s happening on my floor or building, aggregate that and understand how people are using the spaces. If you have multiple sites or buildings, you can look at how different buildings are managed. You could see how to use certain areas better, cool areas down that aren’t being used and make extra savings due to occupancy.’

Call us today to discuss your building lighting requirements. Tel: 0208-540-8287 or sales@novelenergylighting.com.

led ethernet · led lighting · lighting over ethernet · Novel Energy Lighting · office led · office lighting · philips poe · poe · power over ethernet · prolojik

Philips chiefs turn down buyers in favour of a stock market flotation. PLUS: Why laser diodes are the hottest trend in car lighting AND: The winners of the Lighting Design Awards. Lux Today webcast for Tuesday May 10 2016 is presented by Courtney Ferguson.

gooee · led laser diodes · lux awards · lux today · Novel Energy Lighting · philips led ipo · philips lighting ipo